- Specifications

- Photos

- Installations

Overview

Overview

Originally developed to feed bucket elevators from shallow drive over pits, thousands of applications later these units can be found loading out to semi-trailers or returning grain to the leg from a low clearance loadout. Interchangeable hopper gratings and bridge sections allow for custom intake configurations.

- Eliminate water problems common in pit installations. The 16” (2610), 19” (4012), or 26” (4019) deep trench is open at both ends for drainage.

- Unloading rates from 3000 to 17,500 BPH.

- Modular design for variable lengths and discharge heights.

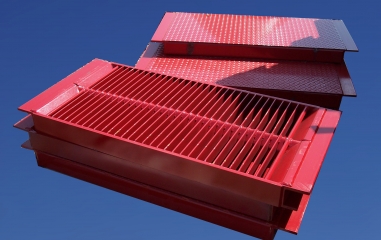

- Cover and grate sections for the “drive over” area are available in various lengths to accommodate various width trenches.

Low-profile design

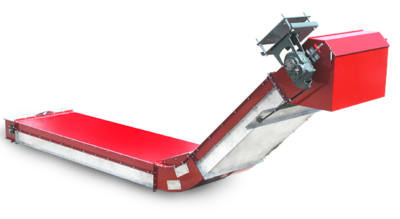

Sudenga Industries pioneered this unique concept in drag chain conveyors. These innovative low-profile conveyors feature capacities up to 17,500 BPH with the advantage of minimized installation cost and the long term durability of drag conveyors. The modular design allows for variable lengths and discharge heights. Conveyors can be configured horizontal (without elbow) or inclined with 22½° or 45° elbows.

Applications

Low-profile conveyors are installed on grade or in a shallow trench to avoid ground water problems. These conveyors are also great in retrofit applications where space is an issue. They were originally developed to feed bucket elevators from shallow drive over pits, now thousands of applications later these units can be found loading out to semi-trailers or returning grain to the leg from a low clearance loadout.

Interchangeable grates

Interchangeable intake grating and solid cover let you set up (and change) the intake area on the conveyor for your particular requirements. You can have an open intake all the way across the drive over area, a center intake for trailers and trucks, or a side intake for wagons. Solid covers used where tires cross the conveyor help keep mud, trash, etc. out of the grain.

Models At a Glance

Model 2610: Up to 7000 BPH

- 3000, 5000 and 7000 BPH unloading rates

- 10 ga. galv. trunking housing

- 22.5°, 45° & 60° elbow and head sections

- 12” x 12” discharge reducer

- Double 81X chain with polyethylene paddles

- 11.5” deck height

- Modular sections available in 1’, 2’, 5’ and 10’ lengths.

- Conveyors require a trough 32” wide and 16” deep. Trench can be left open at ends for drainage.

Model 4012: Up tp 10,000 BPH

- 5000, 7500 and 10,000 BPH unloading rates

- 10 ga. galv. trunking housing

- 22.5°, 45° & 60° elbow and head sections

- Discharge opening 21” x 40” or 12” x 24” reducer

- Double 81X chain with polyethylene paddles

- 14” deck height

- Modular sections available in 1’, 2’, 5’ and 10’ lengths.

- Conveyors require a trough 48” wide and 19” deep. Trench can be left open at ends for drainage.

Model 4019: Up to 17,500 BPH

- 12,500, 15,000 and 17,500 BPH unloading rates

- 10 ga. galv. trunking housing with 7 ga. dividers

- 22.5° & 45° elbow and head sections

- 14” x 14” and 16” x 16” discharge reducer

- Double 81XHH chain with polyethylene paddles

- Outboard mounted pillow block bearings with dust seals

- 21” deck height

- Modular sections available in 1’, 2’, 3’, 5’ and 10’ lengths.

- Conveyors require a trough 48” wide and 26” deep. Trench can be left open at ends for drainage.

Additional Specs: All Sizes

- Combination heavy gauge galvanized and painted trunking sections.

- Painted head, curves and tail sections. (Standard paint color is blue)

- Commercial duty shaft mount gear reducer

- Heavy duty head and tail sprockets on turned ground and polished shafts

- Head mounted inspection/overflow panel

- Intake grates and solid drive over covers can be repositioned for full width, center or side discharge situations. Grates and bridges available in 24” x 32”, 12” x 48”, 24” x 48”.

- Gated grates and flow restrictor pans available

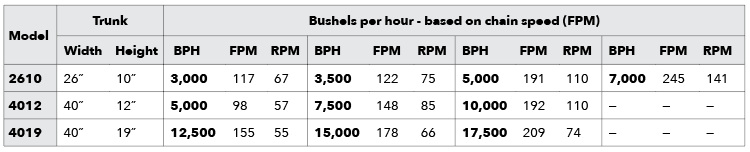

Capacities

Choose a conveyor and chain speed based on capacity required. NOTE: Large conveyors running at slower speeds require less maintenance and last longer than small conveyors run at faster speeds. Also, capacities of larger conveyors can be raised later, if needed, by increasing chain speed.

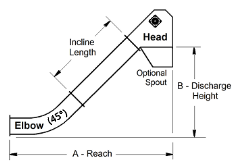

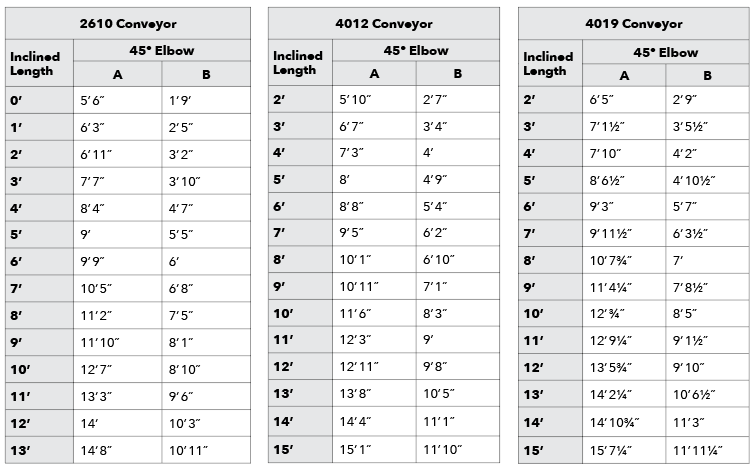

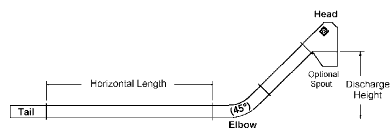

Finding Incline Length

Find your required reach (A) and discharge height (B) in the charts below. The inclined length column will show how much conveyor is needed. The optional spout will reduce the discharge height. Contact factory for spout height.

Find your required reach (A) and discharge height (B) in the charts below. The inclined length column will show how much conveyor is needed. The optional spout will reduce the discharge height. Contact factory for spout height.

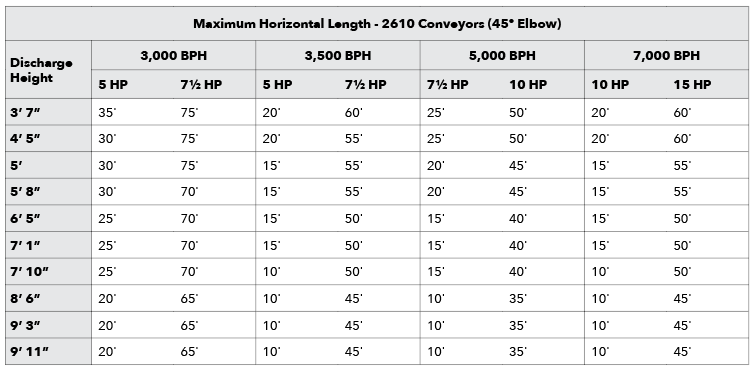

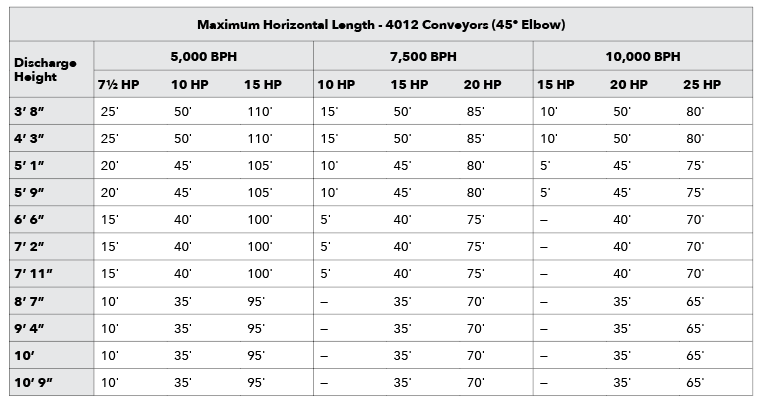

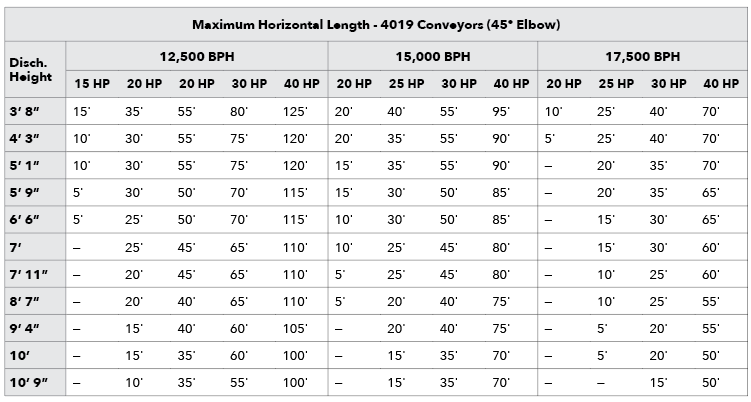

Horsepower Requirements

The following charts show the maximum horizontal length possible, based on discharge height, BPH capacity, and horsepower. NOTE: Horsepowers here are for a conveyor with a 45° elbow. Consult factory for information on specifications or options not shown.

The following charts show the maximum horizontal length possible, based on discharge height, BPH capacity, and horsepower. NOTE: Horsepowers here are for a conveyor with a 45° elbow. Consult factory for information on specifications or options not shown.

Shallow Double Drive Over site in Goodland, KS

This farm site near Goodland, Kansas features a Shallow Double Drive Over (SDDO) receiving station built to accommodate a 42 foot truck/trailer and a low-profile chain conveyor with a 45 degree elbow. Capacity for the system is 10,000 BPH.

Read More

Low-Profile Chain Conveyor near Melvin, TX

Sudenga’s range of low-profile chain conveyors provides an optimal solution for establishing an unloading setup with minimal requirements for dirt and concrete work.

Read More

Low-profile pit near Dimmitt, TX

This site near Dimmitt, TX features a low-profile receiving pit. Sudenga’s 2610 chain conveyor is a great option in areas with water issues.

Read More

Farm Site near Warren, MN

This farm site near Warren, MN features two double-run chain conveyors, a bucket elevator system, and a low-profile receiving pit.

Read More

Farm Site near Adair, IA

Check out this Adair, IA farm site featuring two Double Barrels and low-profile chain conveyor receiving pit from Sudenga.

Read More

Farm Site near Springfield, OH

Check out this Springfield, OH farm site featuring a Double Barrel and low-profile chain conveyor from Sudenga.

Read More

Farm Site near Jasper, MN

Check out this Jasper, MN farm site featuring a Hi-Cap 24 bucket elevator and low-profile chain conveyor from Sudenga.

Read More