- Specifications

- Photos

- Videos

Commercial Grain Bin Sweep

Standard Features

- Clean sweep: Standard on all sweeps. Nylon bristles contact the floor, dramatically reducing the amount of manual sweeping required after bin unloading.

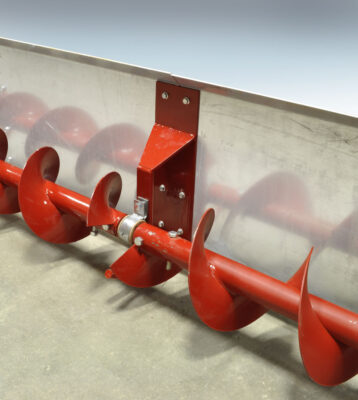

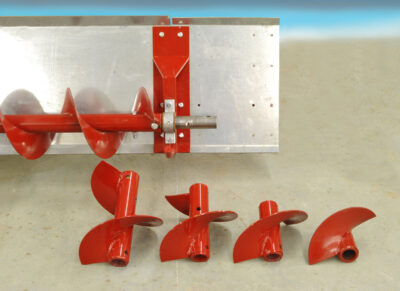

- Sweep extensions: Four sweep extensions and backshields are supplied to allow 3” to 21” of sweep extension in 3” increments. The sweep length is adjusted after installation to make the shortest sweep-to-wall gap in bins that are out of round or have off-center sweep pivots.

- Spring loaded suspension: Automatically, under grain weight, settle the system on skids to protect the sweep and bin floor when the bin is filled. When grain weight is removed, the springs raise the sweeps and tractors to operating height. The tractor carries the sweep during operation, ensuring proper sweep advancement.

- Wood block hanger bearings: Long wearing bearings located in 10 feet intervals.

- The sweeps lead with the flighting for a “full-bite” in tough, stubborn grain.

- Available in electric or hydraulic drive formats.

- Sweeps are advanced by a motorized push tractor or floor mounted track drive.

Options

Trac drive or tractor drive: Both drive types offer positive forward and reverse movement in grain. The drives rest on the bin floor under grain weight and self-raise for operation as the gates remove grain over and around them. No need to enter the bin to prep the sweep.

Patented collector ring: No need to enter the bin! Sweeps with the Sudenga above-floor collector ring option are as close to zero-entry as possible in normal sweep operation. Mounting the electrical collector ring above the floor means less space is required under the floor for the center sump. Sump depth is only 16”. The sweep is permanently installed, and the collector ring provides permanent power to the sweep and tractor drives.

Auto advance: Controls sweep movement by monitoring the sweep motor amperage. When excessive amperage is detected, the auto advance stops the sweep drive. When enough grain is carried away to lower the amperage, the drive unit restarts. A reverse feature senses grain avalanches and backs the sweep up.

Capacities

|

Model |

Flight Diameter |

Capacity (dry corn) |

Bin Diameter |

Max Bin Height |

|---|---|---|---|---|

| D100 | 11¼” | 6,000 BPH | 36-105 ft. | 100 ft. |

| D150 | 11¼” & 16” | 6,000/10,000 BPH | 36-136 ft. | 150 ft. |

Specifications

| Model | Flight Dia. | Flight Ga. | Flight Pipe | Flight Shaft | Back Shield |

|---|---|---|---|---|---|

| D100 | 11.25″ | .250 | 2 7/8″ | 2″ | 10 ga. |

| D150 | 11.25″ | .375 | 2 7/8″ | 2″ | 8 ga. |

| D150 | 16″ | .438 | 4″ | 3″ | 8 ga. |

Zero-Entry

BENEFITS OF “ZERO-ENTRY”

Grain engulfment in storage bins historically leads to more injuries and deaths than sweep entanglement. Some “zero-entry” sweeps require personnel to enter the bin to move grain and manually raise the sweep before it can be engaged. It is during this window, when grain is in its inverted cone state, that a serious risk of engulfment exists. D100 and D150 Sweeps are designed with a self-raising and lowering feature, eliminating the need for personnel to prep the sweep prior to filling or engagement.

Some “zero entry” sweeps require a power cord to be run into the bin. When D100/D150 sweeps are equipped with the Sudenga Above-Floor Collector Ring option, there is no reason to enter the bin as part of normal sweep operation. The sweep is permanently installed, and the Slip Ring provides a permanent source of power for the sweep and tractor drives. When the intermediate sumps have drained enough grain to uncover the sweep, the sweep is started and operated from outside the bin with Sudenga’s Auto Advance panel.

Only normal sweep maintenance typically requires someone to enter the bin. Always follow grain management practices which ensure grain remains in good, free-flowing condition. Be sure proper guards are installed over any exposed floor intakes and always follow proper lock out/tag out procedures whenever working with, or around any equipment.

Read more about the benefits of the zero-entry sweep here.

Testimonial

“With this sweep, Sudenga really has cleaning big grain bins figured out. We’ve had other sweeps in this 105 foot diameter tank, but we finally ended up with Sudenga’s D150 Commercial Sweep. Not only are we able to stay out of the bin more, it actually cut the unload time of the previous sweep by over half simply because it performs better.” READ MORE.