- Specifications

- Photos

- Videos

- Installations

CMS-2020 Commercial Micro Skid

Product Overview

Sudenga’s CMS-2020 commercial micro ingredient system in a NTEP lab certified skid that allows you to accurately measure and deliver small quantities of ingredients to a mixing system. Here are just some of the benefits of using a commercial micro ingredient system:

- Increased accuracy: Our skids are designed to accurately measure and deliver very small quantities of ingredients, which is essential for ensuring consistent feed quality and preventing over- or under-dosing.

- Improved efficiency: By automating your process of measuring and delivering micro-ingredients, you can streamline your feed manufacturing process, reducing the time and labor required to prepare feed batches.

- Reduced waste: Minimize your waste by ensuring that the correct amount of each ingredient is added to each batch of feed.

- Greater flexibility: Our micro-ingredient skids can be customized to meet the needs of your feed mill

- Improved safety: By automating the handling of all micro-ingredients, you can reduce the risk of exposure to hazardous substances.

Overall, the use of a commercial micro ingredient skid can help to improve feed quality, increase efficiency, and reduce waste and safety risks in the animal feed manufacturing process. Contact us today to learn more!

Standard features

- The only NTEP Lab Certified gain-in-weight system in the country.

- Easy integration with existing feed mill systems

- Cost effective solutions for micro ingredient management

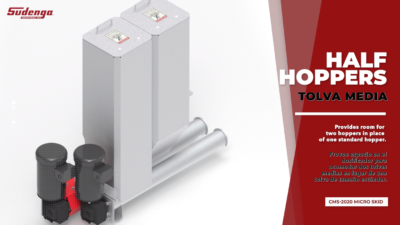

- Various bin sizes available – 3.0 cubic ft. (85 liters), 6.0 cubic ft. (170 liters), 8.0 cubic ft. (227 liters), and 10 cubic ft. (284 liters).

- Center walk-through aisle.

- Standard ¾ HP TEFC motors.

- Carbon steel frame with tough epoxy finish over durable primer.

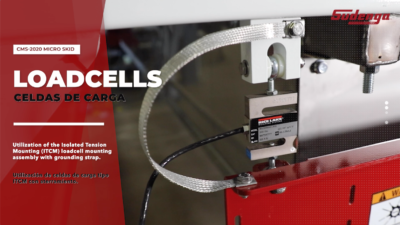

- High accuracy NTEP approved “S” style loadcells and summing junction box.

- To minimize bridging the micro bins are designed with three vertical sides, chamfered corners, and a large conveyor discharge opening.

- 20:1 ratio gearboxes standard.

- English/metric measuring tape in each bin.

- Standard pneumatic rotating drum.

Optional features

- Mechanical agitator for individual bins.

- Individual bin interlock switch to be used in locking individual bins with hinged lids with solenoid release.

- Individual bin dust collection hood.

- NTEP certified scale system with certified scaling vessel.

- Hinged micro bin lids.

- 1 HP, 1.5 HP, 2 HP, and 3 HP motors.

- 10:1 ratio gearbox and 5:1 ration gearbox.

- Class II, Division I motors. (Explosion proof)

- Individual micro bin high/low level sensors for filling micro bins from another source.

- Three point individual FDA hoppers for inventor control or reconciling.

- Individual micro bin inlets for filling micro bins from a bulk container.

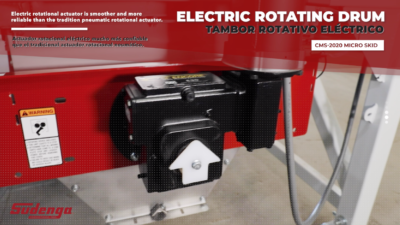

- Electrical rotating drum.

Rotating Drum

- Rotating drum is enclosed in a stainless steel shroud. The shroud is bolt together for easy service.

- 20” (50.8 cm) Rotating drum is rotated with standard pneumatic actuator or optional electric motor with gearbox.

- 24” (61.0 cm) rotating drum is rotated with electric motor with gearbox. (Pneumatic not available)

CMS-4020 Commercial Micro Skid

Product Overview

Scaled bucket systems – this micro skid system comes with a computerized traveling scale for weighting micro ingredients

S-2000 Standard-Duty Micro Skid

Product Overview

Sudenga’s standard-duty micro skid offers cost-effective solutions for micro management and can be easily integrated in existing feed mill systems. Up to 24 six-cubic-foot hoppers available. Systems provide accuracy to within two one-hundredths of a pound.

Standard Features

- NTEP approved “S” style load cells

- Stainless steel flush hopper (gate optional) reduces cross contamination between formulations

- Ribbed poly bin for strength and rigidity. Available in poly or stainless steel. Sizes 3 cu. ft. (85 liters) or 6 cu. ft (170 liters). Custom sizes available in stainless steel bins

- Maintenance free UHMW end bearings on micro hopper discharge auger

- Center walk-through aisles

- VFD controls for high and low speed motor settings

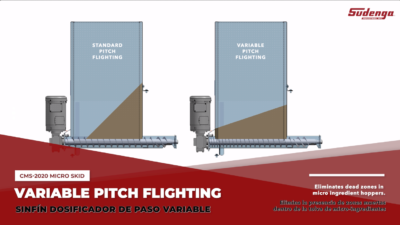

- Half pitch flighting in bin intake and double full pitch flighting on discharge end assures consistent material flow. Available in carbon or stainless steel

Mineral Mix Facility near San Angelo, TX

Check out this installation near San Angelo, TX featuring two bucket elevators, a horizontal mixer, a micro ingredient skid, a round tube auger, and CBX batching software.

Read More

Feed Mill Operation in New Mexico

This CMS-2020 commercial micro skid features 20 6 cubic foot, 14 gauge, stainless steel ingredient bins, a 20″ rotating drum hopper with a 15 cubic ft capacity, and 4 NTEP approved “S” type load cells.

Read More

Hog Feeding Operation near Lismore, MN

Check out this Lismore, MN farm site featuring a painted feed leg, micro skid, weigh hopper, mixer, tote bag system, and loop system.

Read More