- Specifications

- Photos

- Videos

- Installations

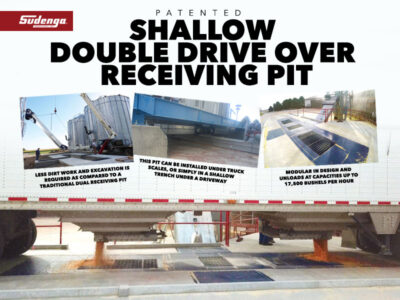

Shallow Double Drive Over Receiving Pit

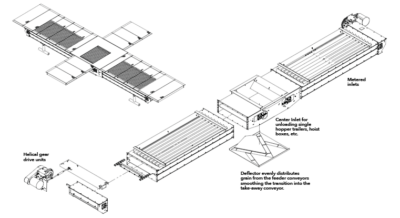

FEATURES

- Shallow pit requirement: only 38” or 45″ trench depth.

- Enclosed conveyor: trench can be open at the end for water drainage.

- Designed for 40’-53’ grain trailers.

- Modular system can be custom configured to fit your application

- Installed under truck scales or in a shallow trench under a driveway

- Minimizes concrete and dirt work during installation, while maximizing efficiency for the operation once installed

- Unloads a typical grain trailer at capacities up to 17,500 bushels per hour

WHAT MAKES SUDENGA'S PERMANENT PIT UNIQUE?

Traditional, dual receiving pits require a very deep hole to be dug requiring significant excavating work, yards of concrete and rebar, and hours of on-site fabrication and equipment installation. Equipment that goes into these deep pits requires more height and operational horsepower. Deep, dual inlet pits are often very expensive to install and maintain as a result. Ground water seepage issues are often seen with these pits as well. Potentially unsafe housekeeping requirements may be a factor as confined space entry is required for repair or clean out of the equipment and pit.

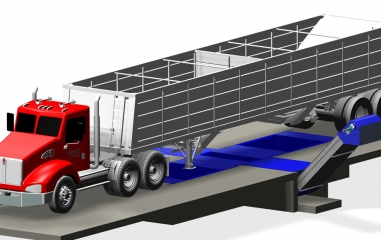

With our permanent, low-profile, dual inlet receiving pits, the installer has a choice of how deep they want to install the system in the ground. In some cases, the unit can be installed on grade, requiring only site leveling, or, the installer can choose to dig a shallow trench (often less than 4’ deep) where much less rebar and concrete is required. Access to the equipment once installed is often as simple as removing a grate section. The whole system is modular, so it can fit a variety of site layouts and applications.

Improve safety and efficiency: Less dirt work and excavation is required so less time and resources are necessary to install. Installation is easier as most of the installation work is done on grade. Less support equipment is necessary, like cranes and backhoes, as the drive over equipment can often be installed with smaller lifting equipment and no need to dig big holes. The equipment surrounding low-profile pits can often be less expensive because the heights are shorter as equipment can be installed on grade. Finally, eliminating a deep pit ensures that personnel are not required to enter a confined space to clean or repair equipment associated with the grain pit.

With our permanent, low-profile, dual inlet receiving pits, the installer has a choice of how deep they want to install the system in the ground. In some cases, the unit can be installed on grade, requiring only site leveling, or, the installer can choose to dig a shallow trench (often less than 4’ deep) where much less rebar and concrete is required. Access to the equipment once installed is often as simple as removing a grate section. The whole system is modular, so it can fit a variety of site layouts and applications.

Improve safety and efficiency: Less dirt work and excavation is required so less time and resources are necessary to install. Installation is easier as most of the installation work is done on grade. Less support equipment is necessary, like cranes and backhoes, as the drive over equipment can often be installed with smaller lifting equipment and no need to dig big holes. The equipment surrounding low-profile pits can often be less expensive because the heights are shorter as equipment can be installed on grade. Finally, eliminating a deep pit ensures that personnel are not required to enter a confined space to clean or repair equipment associated with the grain pit.

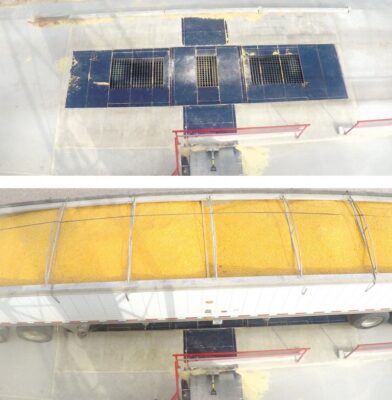

Shallow Double Drive Over site in Goodland, KS

This farm site near Goodland, Kansas features a Shallow Double Drive Over (SDDO) receiving station built to accommodate a 42 foot truck/trailer and a low-profile chain conveyor with a 45 degree elbow. Capacity for the system is 10,000 BPH.

Read More

Shallow Double Drive Over Site in Louisiana

At this site in Louisiana, a Shallow Double Drive over is used to unload grain, which is then transferred over to barges that transport it to New Orleans.

Read More

Farm Site near Burt, IA

Check out this Burt, IA farm site featuring a Senior 36 bucket elevator system and a shallow double drive-over receiving pit from Sudenga.

Read More