Top-Selling Products of 2025

A look at the Sudenga equipment customers relied on heavily in 2025 across grain and feed applications

A look at the Sudenga equipment customers relied on heavily in 2025 across grain and feed applications

In 2025, Sudenga customers invested in equipment that improved throughput, reduced handling time, and held up under daily use. From harvest receiving to feed production, these products rose to the top because they solve real-world challenges across grain and feed operations.

Low-profile, high-capacity receiving solutions designed to speed up truck unloading with minimal site preparation. A practical fit for farms, elevators, and feed mills looking to reduce bottlenecks during peak delivery periods.

Best for: Harvest-time receiving; temporary or permanent setups; operations needing portability and fast truck turns

Built for higher-volume facilities, the Double Drive Over allows simultaneous unloading from hopper-bottom trailers while maintaining a shallow installation depth.

Best for: Commercial grain and feed facilities; high-throughput receiving; sites wanting big capacity without deep pits

A proven bin unloading solution offered for bins up to 80’ in diameter, built for consistent performance and long-term reliability. Installs in dryer bin floors as low as 13 inches.

Best for: Standard farm bins and light commercial bin applications; consistent, reliable unloading; operations wanting a straightforward, proven sweep

Engineered for large-diameter bins and demanding grain conditions, D-Series sweeps offer zero-entry operation and heavy-duty construction for commercial-scale unloading.

Best for: Large commercial storage; tough grain conditions; zero-entry unloading environments

Designed to move high volumes efficiently while minimizing excavation and installation costs. A foundational component in many complete grain handling systems.

Best for: New construction and retrofits; continuous, high-volume conveying; facilities with site or groundwater constraints

A staple of vertical grain movement in both ag and feed facilities. Multiple models and capacities support a wide range of system designs. Most popular models in 2025 include 3500 bu/hr Medium 24 and 10,000 bu/hr Senior 36 in powder coated finishes.

Best for: Vertical conveying; high-capacity, continuous-duty applications; integrated grain and feed systems

High-output portable augers built for fast grain movement in the field or around the yard.

Best for: Bin filling; grain piles and temporary transfer; high-capacity portable applications

A versatile portable auger solution available in multiple diameters, lengths, and drive options to fit daily grain handling needs.

Best for: Bin loadout applications; general grain handling; dryer and bin applications; flexible power and configuration needs

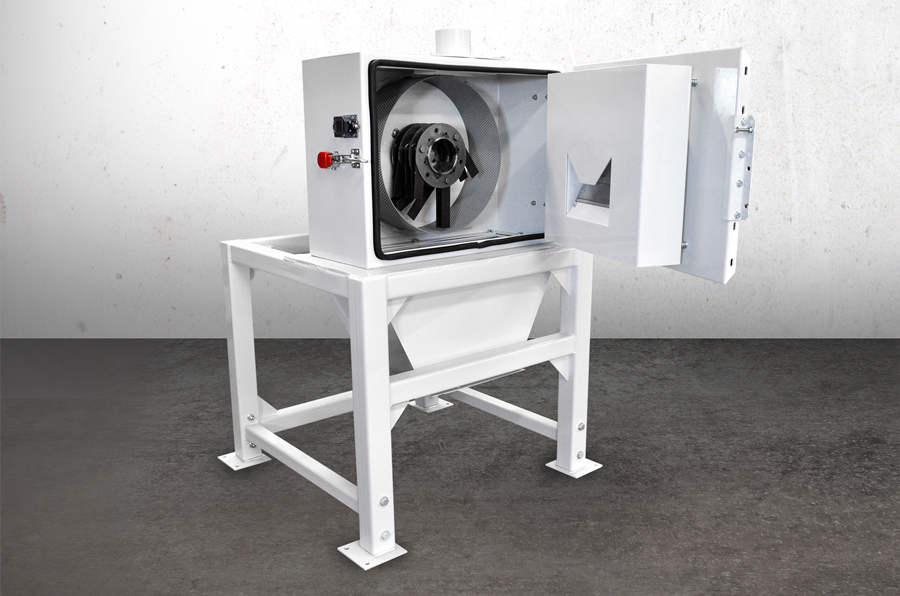

Designed for consistent grinding and reliable throughput in feed production systems.

Best for: Feed mills; on-farm feed processing; skid-mounted or system-integrated setups

Built to deliver uniform mixing across a wide range of feed formulations and batch sizes.

Best for: Consistent feed quality; batch and continuous operations; system-integrated feed production

Accurate, repeatable micro batching solutions that integrate into larger feed systems without unnecessary complexity.

Best for: Precise ingredient control; accurate ingredient tracking history; improved ration consistency; scalable feed mill upgrades

A proven solution for reclaiming grain piles quickly and efficiently when grain ends up on the ground. 11,000 bu/hr capacity loads a semi trailer in as little as 6 minutes.

Best for: Grain pile cleanup; emergency reclaim situations; high-capacity grain movement

Across ag and feed operations, Sudenga’s top-selling products in 2025 reflected a clear set of priorities. Customers consistently chose equipment designed to function as part of a complete system, built with durable construction for long-term use, and flexible enough to scale as operations grow. Whether upgrading a single component or planning a full facility, these solutions represent proven equipment built to work together with confidence.

A new approach to bin unloading that bridges the gap between traditional farm sweeps and full commercial underbin systems and zero entry sweeps. Designed to deliver high-capacity performance across a wide range of bin sizes while fitting into economical 13” dryer floors.

Best for: Large farms and commercial storage; high-capacity bin unloading; projects where floor depth is limited

Hammermill skid combined with the hammermill process control panel allows you to automate your feed grinding process.

Best for: Dairy commodity processing applications;

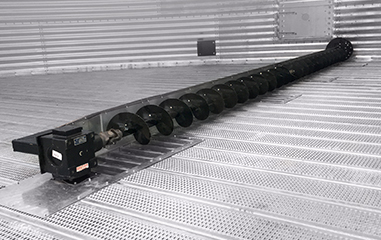

Installed inside livestock operations to feed cage feeders. Lengths to 127’ and capacities to 1,800 bph. Lowest maintenance, long lasting and quietest way to feed livestock inside barns.

Best for: Poultry cage feeding operations

Across ag and feed operations, Sudenga’s top-selling products in 2025 reflected a clear set of priorities. Customers consistently chose equipment designed to function as part of a complete system, built with durable construction for long-term use, and flexible enough to scale as operations grow. Whether upgrading a single component or planning a full facility, these solutions represent proven equipment built to work together with confidence.

Request A Quote