- Specifications

- Photos

- Installations

Incline

Standard Features

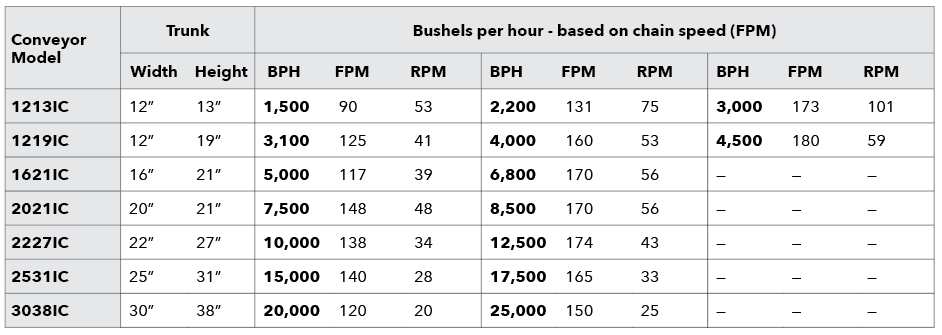

- 1,500 to 25,000 BPH

- 5° through 60° elbows

- Rack and pinion outlets with electric or manual opener

- Head Section: Flame cut sprockets on shafts up to 6-1/2″ (based on conveyor size); outboard mount pillow block bearings; UHMW shaft dust seals; shaft mount helical drive

- Tail Section: Flame cut sprockets on shafts up to 4-15/16″ (based on conveyor size); threaded rods provide chain tension

Capacities & Dimensions

Choose a conveyor and chain speed based on capacity required. Choosing a larger conveyor running at slower speeds requires less maintenance than smaller conveyors running at faster speeds. Also, capacities can be raised later, if needed. NOTE: The angle of incline does not significantly alter capacities due to paddle design. Use the capacity figures, below, for all inclines.

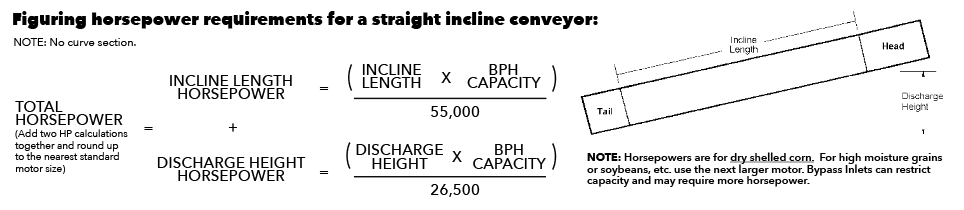

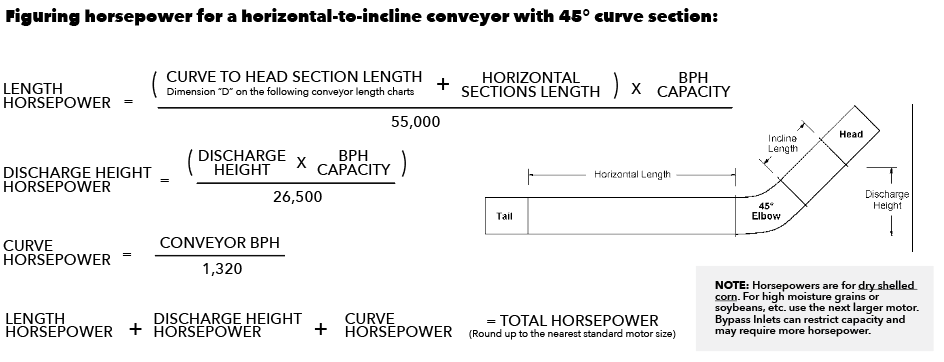

Figuring Horsepower

Farm Site in NW Iowa

Check out this northwest Iowa farm site featuring a Medium 30 Bucket Elevator, an Incline Chain Conveyor, and a Reclaim Conveyor.

Read More