- Specifications

- Photos

- Installations

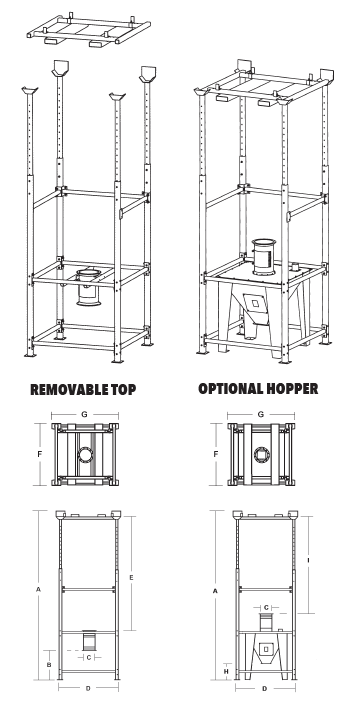

Bulk Bag Stands

General Info

Add ultimate versatility to your feed system using Sudenga’s bulk bag stands. Two-piece design allows bag replacement at ground level. Unload in a variety of ways including rigid augers, flex augers, chain loop, etc.

STANDARD FEATURES

Versatile design allows for a variety of applications.

Operated by existing feed mill controls, whether automated or manual.

Two-piece design allows bag replacement at ground level for safer, simpler bulk bag handling.

Suitable for major, minor, and micro ingredient storage.

Can be adapted to a variety of discharge conveyor systems, including rigid augers or flex augers.

| Dimensions | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A (min.) | A (max.) | B | C | D | E (min.) | E (max.) | F | G | H | I (min.) | I (max.) | |

| Inches | 127-1/4″ | 175-1/4″ | 30″ | 12″ | 60″ | 71-1/4″ | 119-1/4″ | 63″ | 66″ | 16″ | 52-3/4″ | 100-3/4″ |

| Centimeters | 324 | 446 | 76.2 | 2.54 | 152.4 | 181 | 303 | 160 | 168 | 40.6 | 134 | 256 |

Hog Feeding Operation near Lismore, MN

Check out this Lismore, MN farm site featuring a painted feed leg, micro skid, weigh hopper, mixer, tote bag system, and loop system.

Read More

Commercial Tote System

Check out this commercial tote bag system. Designed to handle major, minor, and micro ingredients. Cage style system allows for moving tote bags with a lower center of gravity.

Read More