- Specifications

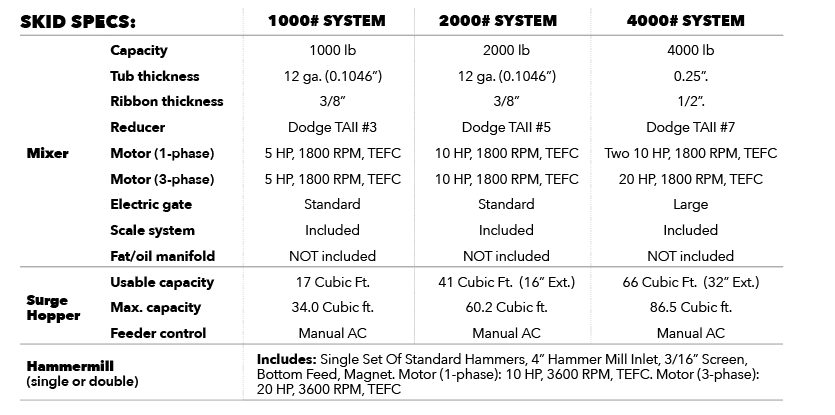

- Photos

- Installations

Feed Batching Systems

Benefits

- Compact: Feed batching skids are typically compact in size and can be installed in tight spaces, making them a space-saving solution for small feed mills or on-farm feed mixing operations.

- Efficient: Batching skids can be used to make and mix small batches of feed quickly and efficiently, reducing the need for manual labor and saving time.

- Quality: The use of automated systems helps to ensure you get a consistent, high-quality feed product.

- Cost-effective: Batching skids are often less expensive than larger, more complex batching systems, making them a cost-effective option for small-scale feed operations. They can even be retrofitted into your existing installation.

Why invest in a batching skid?

Are you looking for a more efficient and reliable way to manage your feed production? If so, look no further than Sudenga’s state-of-the-art feed batching system. Our feed batching systems are designed with the needs of modern farmers in mind. Our skids can help you reduce waste, save time, and increase productivity, all while providing the highest quality feed for your livestock.

Our skids are customizable, and can be retrofitted into an existing installation. Whether you are raising poultry, hogs, cattle, or any other type of livestock, our feed batching system can help you optimize your feed production process and improve your bottom line. Contact us today to learn more about how Sudenga’s feed batching systems can help you achieve your goals and take your farm to the next level.

Make more feed—faster, with a batching skid from Sudenga.

2 Popular Formats

ST-Series

- Horizontal mixer (1000, 2000, or 4000 lb)

- Surge hopper

- Hammermill (single or double)

- Motor control panel (optional)

S-Series

- Horizontal mixer (1000, 2000, 4000, or 6000 lb)

- Hammermill (optional)

- Motor control panel (optional)

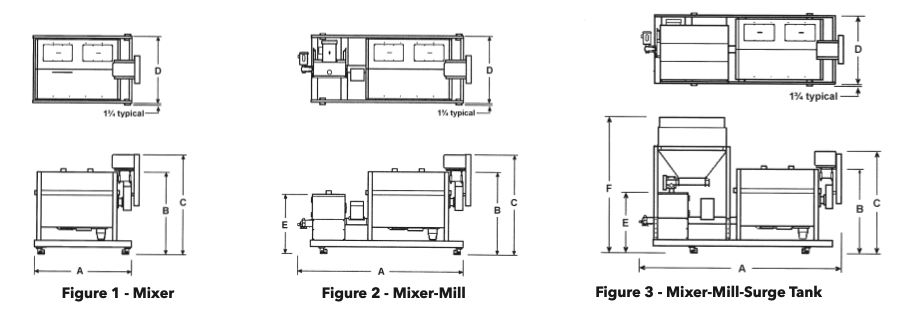

Dimensions

ST-Series

General

Sudenga’s ST-Series feed batching skids feature a horizontal mixer (1000, 2000, or 4000 lb options), surge hopper, and hammermill (single or double). Add in Sudengas’ motor control panel (sold separately) for an all-in-one batching solution.

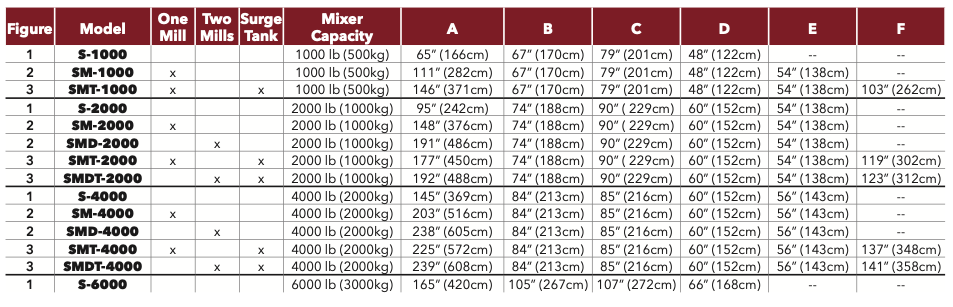

Specifications

Motor Control Panel

Add in Sudengas’ motor control panel for an all-in-one batching solution.

SYSTEM INCLUDES:

- Motor control panel with disconnect.

- Single door standard. Double door option.

- 8 ingredient contactors (2 HP) with the option to add more.

- 2 unloading contactors (3 HP) with the option to add more.

S-Series

General

Sudenga’s S-Series feed batching skids feature a horizontal mixer (1000, 2000, 4000, or 6000 lb options), and an optional hammermill. Add in Sudengas’ motor control panel (sold separately) for an all-in-one batching solution.

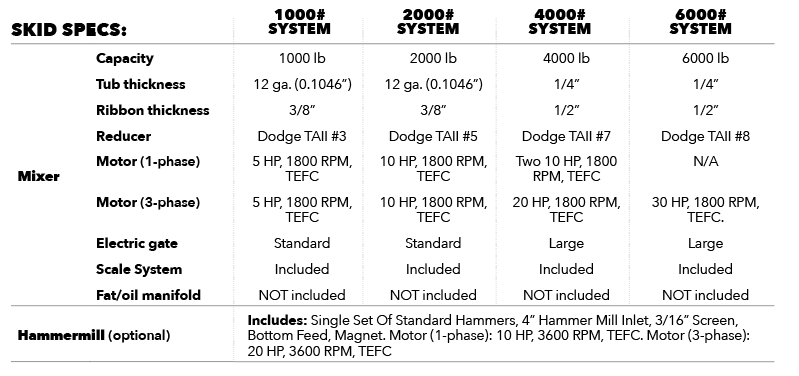

Specifications

Motor Control Panel

Add in Sudengas’ motor control panel for an all-in-one batching solution.

SYSTEM INCLUDES:

- Motor control panel with disconnect.

- Single door standard. Double door option.

- 8 ingredient contactors (2 HP) with the option to add more.

- 2 unloading contactors (3 HP) with the option to add more.

Feed Room Install

This feed room install from features a complete Sudenga feed batching system. This skid includes a two ton mixer with a pair of 25 hp hammer mill’s and a surge hopper with supporting augers.

Read More