- Specifications

- Photos

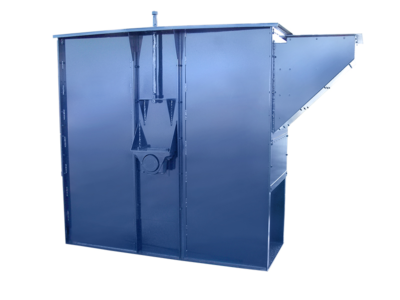

Bucket Elevator Systems

Commercial

Standard Features

- Sudenga Industries offers bucket elevators that exceed 200′ in discharge height and capacities from 220 to 25,000 CFPH. Elevator legs that fall outside the catalog range can easily be quoted to spec.

- Industrial Design. Heavy components. Welded construction is standard. Honest Capacity Ratings.

- Drum Style Head Pulleys. Holz replaceable slide lagging standard on SR 36, 42 & 48, and Hi-Cap Models 24, 30, and 48. Rubber lagging with herringbone pattern standard other sizes. All oil and fire resistant. Self-cleaning slatted boot pulley standard – all models.

- Goodyear Pathfinder Supreme rubber belting, static conducting, best for oil and flame resistance. A variety of specialty belts can also be utlized including PVC, food grade and high temp belts.

- Double row spherical roller pillow block bearings standard on Medium “24” and larger legs, pillow block ball bearings on Model “C” 6” and Model “12” Junior legs. Split bearings available for easy replacement

- Turned, ground, and polished head and boot shafts, for guaranteed true dimension and straightness.

- Durable polyethylene vented cups standard for better cup fill and discharge; increased venting available for light or hard to handle products. Nylon and other specialty cups are available.

- Hinged and gasketed inspection ports, with screens for safety, removable for service access.

- Trunking section lengths in 2’ increments allow desired discharge height.

- Trunking inspection port can be located in 4 locations for operator visibility.

- Metal backed urethane or rubber lined discharge and transition standard on 36” diameter and larger, optional on smaller units.

- Pre-welded/assembled platforms make for easy and quick assembly. Lifting eyes on head sections are standard. Jacking bolts for head shaft alignment standard on 24” and larger.

- Jig assembled and continuous welded construction for superior durability and hassle free installation. Heavy plate trunking flanges standard on most sizes.

- Phosphatized, primed, and painted with a 2-part polyurethane paint. Blue paint standard. White, red or gray optional at no charge. Hot dipped galvanized construction optional.

- A variety of accessories are available along with support towers, catwalk, trussing kits, spouting and distributors.