Roller Mill

Sudenga’s Roller Mill is available in single, double, and triple pair high setups with capacities up to 36 TPH at 500 microns. Available with roll gap automation and load compensating controls.

Read More

Micro Ingredient Systems

Commercial and standard duty micro ingredient systems provide accuracy to within two one-hundredths of a pound. Systems offer a VFD drive with PLC interface. Up to 24 six-cubic-foot hoppers available in any configuration to fit the application.

Read More

Feed Batch Controls

Automate an entire feed processing system—from grinding to mixing to inclusion of micro ingredients—all through one control panel. The CBX batching software features a user-friendly interface making it easy to create and manage feed batches, saving you time and increasing overall efficiency.

Read More

Loss-In-Weight Micro Skid

Weigh and add ingredients automatically for the fastest, most efficient, and most accurate batching possible. Avoid handling medications and additives with the Sudenga Loss-In-Weight system. NTEP certified Loss-In-Weight systems are available.

Read More

Hammer Mills

An integral part of any feed production setup is a reliable and low maintenance hammer mill. Various screen sizes are available to ensure proper particle size and varying motor horsepower are available to fit the capacity needs of your job.

Read More

Horizontal Mixers

Sudenga’s horizontal mixers and pre-mixers are available in sizes from 500 to 6,000 pounds. The double ribbon design ensures thorough mixing of all types of products from fine powdered materials to coarse ground ingredients. A great addition to any size feed operation.

Read More

Infinifeed Loop

Move feed quietly and efficiently with the Infinifeed Loop system. The continuous loop design features Sudenga’s proven technology chain conveyor. It is available with single or double inlet hoppers in lengths up to 127 feet and capacities up to 1,800 BPH (2200 CFPH).

Read More

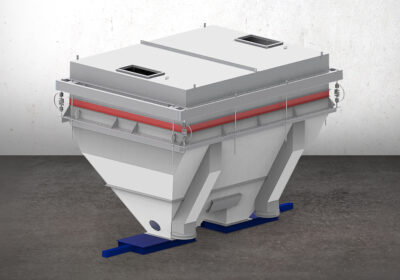

Mixer / Surge Hopper

Increase production with a specially designed surge hopper for your horizontal mixer. Sudenga’s Horizontal Mixer / Surge Hopper combination can increase your production time with reduced batch cycle times and fast, efficient clean out.

Read More

Bulk Bag Stands

Add the ultimate versatility to your feed system using Sudenga’s bulk bag stands. Unload in a variety of ways, including rigid augers, flex augers, chain loop, etc.

Read More

Weigh Hopper

Weigh hoppers from Sudenga increase batching capacities and feed weighing accuracy thanks to a CBX monitoring computer. Select from weigh hoppers that can handle minor scale weighing to major scale weighing.

Read More

Feed Batching Skids

Sudenga’s skid-mounted feed batching systems provide a compact, all-in-one-solution that can be customized for your operation. Systems include options for mixers (1,000-6,000 lbs), hammermills (single, double, or none), surge hoppers, and motor control panels.

Read More

Double Barrel Chain Conveyor

Double Barrel Chain Conveyors have the benefits of a traditional chain conveyor (durability, low horsepower consumption and great capacity), but can be installed anywhere a traditional auger, air system or drag chain conveyor might be installed. Sudenga’s 6, 8, 10, or 12 inch systems are available with capacities up to 10,000 bushels per hour. Plus, the system is modular so lengths can be tailored to your specific application.

Read More