System Details

Learn more about Sudenga’s patent-pending Double Barrel Power Sweep:

Questions? Email us at sales@sudenga.com

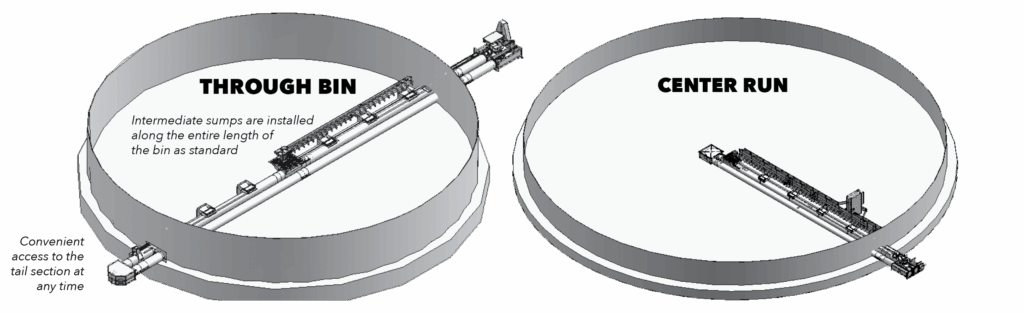

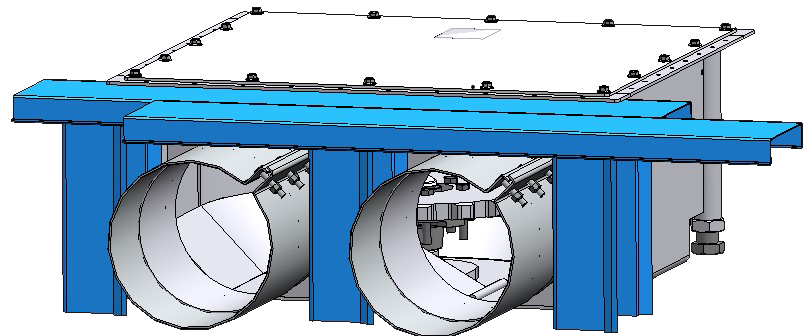

Two underbin designs to choose from

Sudenga’s Double Barrel Power Sweep was engineered to deliver high-capacity bin unloading in applications where traditional commercial underbin systems are impractical or cost-prohibitive. By fitting a high-capacity chain-and-paddle conveyor into a low-profile, 13-inch floor system, the design eliminates the need for deep tunnels and heavy bin foundations. The horizontally oriented twin-barrel configuration allows the underbin to either terminate at the center of the bin or extend fully through, adapting to site-specific layout and structural requirements. With the zero-entry sweep permanently mounted inside the bin and all drives located externally, the system improves safety, reduces labor, and delivers unloading capacities up to 6,500 bushels per hour with lower horsepower and minimal maintenance. The result is a complete bin unloading solution designed for large-diameter bins with significantly reduced installation complexity.

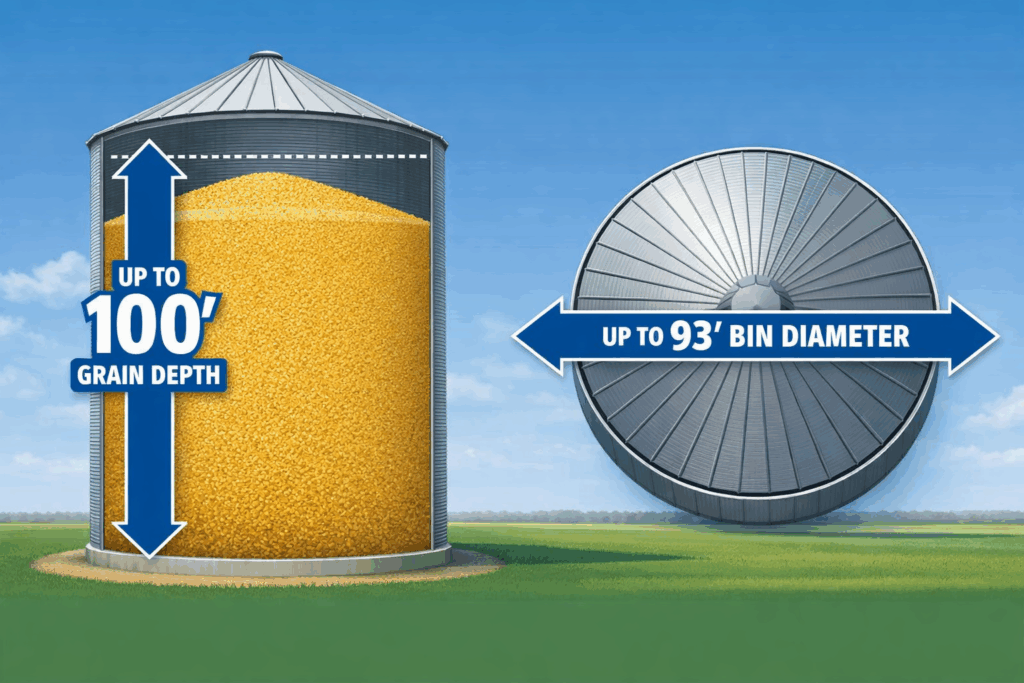

Built for large-diameter bins with high grain loads

The Double Barrel Power Sweep is engineered to perform in large-diameter grain bins and deep grain conditions, supporting installations in bins up to 93 feet in diameter with grain depths approaching 100 feet. As bin size and grain depth increase, key system components are scaled accordingly to maintain performance and structural integrity. Elements such as the back shield, drive components, and gearboxes are designed to handle increased grain loads while preserving controlled material flow and low horsepower requirements. This scalable design allows the system to adapt to a wide range of bin sizes without requiring changes to foundations, tunnels, or floor height.

Auger-style functionality with drag-system performance

Traditional auger-style power sweeps have long been used for bin unloading, but increasing bin sizes and higher unload demands have pushed many operations toward drag-style systems. The Double Barrel Power Sweep bridges this gap by combining the familiar operating characteristics of auger-style power sweeps with the higher capacity of a drag-based conveyor system. By utilizing a chain-and-paddle conveyor configuration beneath the bin floor, the system delivers unloading rates up to 6,500 BPH while maintaining low horsepower requirements. This approach provides increased throughput and durability compared to conventional screw-based systems, without the installation complexity typically associated with full commercial under-bin drag systems.

Sump design and grain flow

The Double Barrel Power Sweep features large sump openings designed to support smooth grain flow across a wide range of conditions, including free-flowing grain and material containing crusts, frozen chunks, and foreign material. The design maintains consistent grain flow from the sweep to the center sump regardless of sweep position within the bin. Intermediate sumps also serve as access points for maintenance, and an emergency sump near the center sump is included as a standard feature.

Floor supports

The Double Barrel Power Sweep features a low-profile underbin design that requires only a more economical 13” floor support, unlike traditional drag conveyor bin unload systems. In many installations, standard floor supports are sufficient rather than full bridge-style supports. Final floor support requirements are determined by the bin manufacturer based on bin diameter and sidewall height. Where taller floors are needed, spacer options allow the system to adapt while maintaining proper load distribution and long-term structural performance.

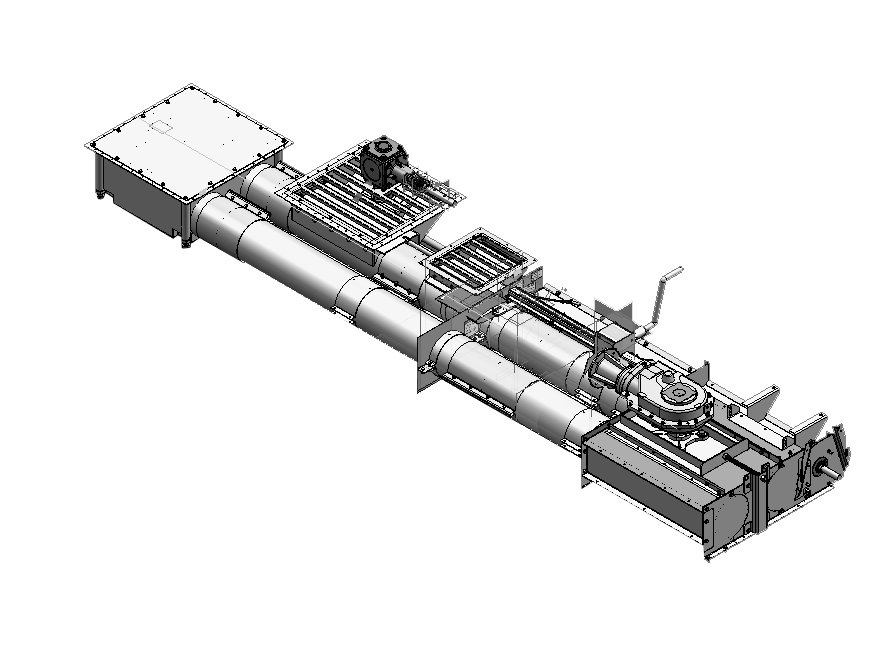

Dual-motor drive configuration

The discharge head is designed with a dual-motor configuration to balance performance and efficiency during bin unloading.

- Underbin Motor: One motor is dedicated to operating the under-bin system for steady, controlled grain flow.

- Sweep Motor: A second motor independently drives the power sweep, allowing consistent sweep operation without overloading the system.

By separating these functions, the system maintains controlled grain movement while keeping overall horsepower requirements relatively low. Eliminating a sweep arm shifter gearbox further reduces moving parts and makes it easier to adjust sweep arm BPH.

Single-phase power compatibility

The system is designed to operate with low horsepower requirements and is compatible with single-phase power in bins up to 93 feet in diameter. This capability is particularly beneficial for rural grain storage installations where three-phase power may not be readily available or cost-effective to install. By reducing overall power demand while maintaining high unloading capacity, the system simplifies electrical infrastructure requirements without compromising performance.

Intelligent mechanical push tractor

For larger bin diameters and increased grain depths, the system utilizes a mechanical push tractor that monitors sweep fill levels and regulates sweep advancement accordingly. The tractor autonomously engages and disengages to maintain optimal material loading, advancing only when more grain is needed and stopping when it is at capacity. The tall backshield contains the large avalanches that come with larger bins plus the tractor allows the sweep to backup when need be, keeping grains on the front side of the backshield. This fully mechanical control strategy delivers functionality comparable to electronic systems while eliminating electrical components and wiring inside the bin. The result is a fully integrated, zero-entry sweep operation that improves operational safety, simplifies installation, and removes the need for in-bin monitoring during unloading.

No electrical components inside the bin

Although the system incorporates an intelligent mechanical drive approach, there are no electrical components located inside the bin. This design maintains consistent operation while eliminating in-bin electrical systems.

Patent pending technology

The Double Barrel Power Sweep incorporates patent-pending design elements, reinforcing our commitment to innovation in bin unloading solutions.