Sudenga’s patent-pending Double Barrel Power Sweep features a wide variety of applications!

- Designed for bins ranging from 18’ to 93’ in diameter with grain depths up to 100’.

- Commercial-level performance without a commercial underbin system.

- Lower installation cost than a standard commercial system.

- Proven drag conveyor design delivers strength and longevity.

- Works for new or retrofit installations.

- Compatible with floor heights as low as 13 inches.

- Zero-entry design improves safety.

- Large sump openings for smooth grain flow.

What Sets This System Apart

The Double Barrel Power Sweep was engineered to address the structural, installation, and operational challenges that limit conventional bin unloading systems

Low-profile installation – The Double Barrel Power Sweep installs under floors as low as 13 inches, helping eliminate tunnels, deep foundations, and added construction cost. The compact profile supports both new builds and upgrades across farm and commercial sites. MORE>

High-capacity performance – With unloading capacities up to 6,500 bushels per hour, the Double Barrel Power Sweep delivers commercial-level throughput for bins ranging from 18 to 93 feet in diameter, making it a high-capacity solution across a wide range of bin sizes. MORE>

Chain-and-paddle durability – The under-floor chain-and-paddle conveyor design reduces wear compared to traditional screw conveyors. This approach delivers long service life, consistent grain flow, and reduced maintenance over time.

Broad range of applications – The Double Barrel Power Sweep was designed to work in a wider range of bin sizes, floor heights, and site conditions than conventional unloading systems.

True zero-entry operation – One of the key features is this sweep’s zero-entry sweep design! When the bin is full, the sweep automatically lowers itself to the floor, distributing the load evenly. Before operation begins, it raises itself off the floor—no manual adjustment needed. This automation eliminates the need for personnel to enter the bin to position the sweep or shovel before engaging the sweep. WATCH VIDEO

Auto advance push tractor – During sweep operation the system includes a mechanical push tractor that monitors the sweep’s fill level and controls its advancement. It starts and stops the sweep’s movement as needed, again removing the need for someone to be inside the bin to monitor progress. MORE>

External drive and controls – All motors and controls are located outside the bin, avoiding in-bin wiring and the need for explosion-proof electrical components. This simplifies installation, lowers electrical costs, and improves long-term serviceability.

Low horsepower requirements – The Double Barrel Power Sweep moves high volumes of grain while requiring less than half the horsepower of comparable screw conveyor systems, lowering energy consumption and simplifying electrical infrastructure.

Compatible with single-phase power – The system can operate on single-phase power, making it a practical option for rural sites where three-phase power is unavailable or cost-prohibitive.

Cost effective solution for large bins – Engineered for bins up to 93 feet in diameter with eave heights up to 100 feet, the Double Barrel Power Sweep delivers power sweep simplicity in large bins while avoiding the tunnels, foundations, and installation costs of under-bin systems.

Sweep configurations by bin size

Sweep configuration is matched to bin diameter to ensure consistent performance, controlled advancement, and reliable unloading. All three setups are based on sweep solutions already proven through Sudenga’s existing line of bin sweeps and unloading systems.

- Up to 43′ 4″: Low-profile sweep with 11:1 reduction end wheel

- 48′ to 49′ 6″: Low-profile sweep with 20:1 reduction end wheel

- 54′ to 93′: Gearbox-driven Mini-D sweep arms paired with a Mechanical Auto Advance Tractor (MAAT) for controlled, automated sweep advancement. The mechanical design delivers the functionality of electronic push tractors without the added cost, wiring, or electronic complexity.

All sweep arms are powered by externally mounted gearboxes, eliminating wiring and electric motors inside the bin. This external drive design simplifies installation, improves long-term serviceability, and keeps all electrical components accessible outside the bin. Mechanical sweep advancement eliminates the need to run electrical wiring to the sweep or tractor.

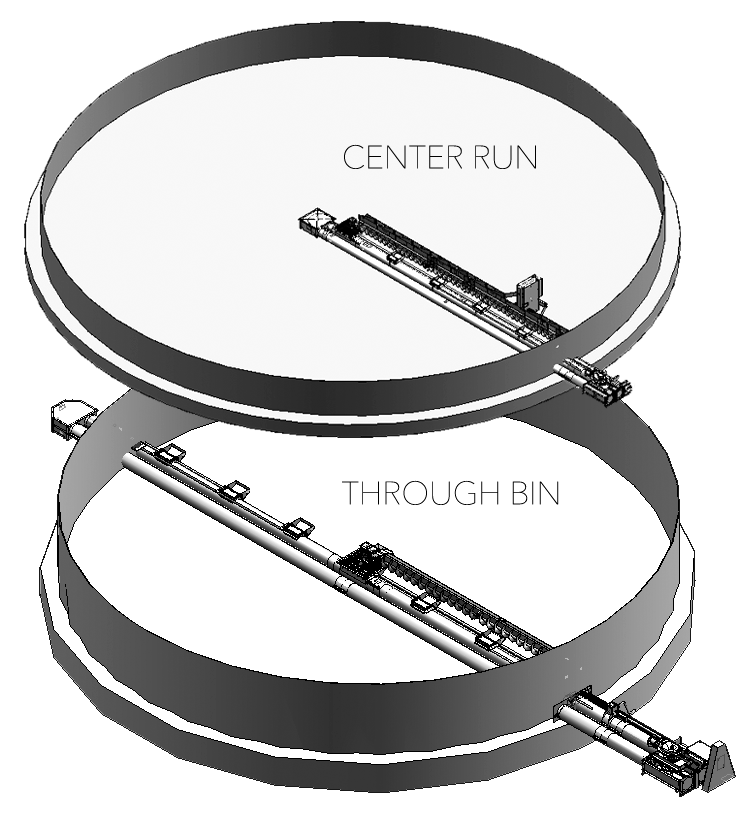

Two underbin designs

The Double Barrel Power Sweep offers two underbin formats to accommodate different layouts, budgets, and operational preferences.

- Center-Run: A compact, cost-effective option that runs to the center of the bin, offering the same low underbin height, high capacity, and low maintenance as the through bin.

- Through-Bin: This design features an underbin system that extends across the entire bin, allowing for intermediate sumps that run the entire length of the underbin. This format also provides easy access to the tail at all times.

Both configurations are designed to maintain consistent grain flow from the sweep to the center sump throughout the unloading cycle. Large sump openings promote smooth grain flow and reduce the risk of plugging in difficult grain conditions.

PATENT PENDING

Common Applications

Common applications for the Double Barrel Power Sweep include:

- Large farm grain storage

- Commercial grain facilities

- Dryer bins with 13” floors

- New construction or retrofit projects

- Bins with sidewalls over 60’ where traditional sweeps fall short

Frequently Asked Questions

Still have questions? Here are answers to common ones about the Double Barrel Power Sweep.

It features an innovative underbin conveyor design that delivers commercial-level unloading capacity while fitting bin floors as low as 13 inches, eliminating the need for tunnels and deep foundations.

Yes. The low-profile design makes it ideal for retrofit installations where floor height is limited.

The Double Barrel Power Sweep offers a maximum operating capacity of 6,500 bushels per hour. For applications that require less capacity, the unit can be operated at a reduced speed.

The system is suitable for sidewall heights up to 100 feet.

Sidewalls up to 60 feet use standard dryer floor supports.

Sidewalls exceeding 60 feet require an LJI low-profile tunnel support kit.

The system is designed for bins ranging from 18 to 93 feet in diameter.

Yes. It is designed to scale from high-capacity farm storage to full commercial grain operations.

By eliminating tunnels, deep foundations, and bridge supports, installation time and total project cost are reduced.

Yes. Extension sections are available in 2-foot increments up to 10 feet, allowing for flexible installation options.

The Double Barrel Power Sweep can be installed in dryer floors as short as 13 inches. For floors with taller supports, installers simply shim the unit to the proper height.

No. The sweep is permanently mounted and externally driven, allowing zero-entry unloading.

Yes. The system can operate on single-phase power for many installations, depending on bin size and configuration.

The system uses two motors—one for the underbin conveyor and one for the sweep. This design reduces the horsepower required for each component, expands application flexibility, eliminates wiring inside the bin, and helps lower electricity costs.

The Double Barrel Power Sweep is the only underbin floor conveyor that can be installed to the center of the bin, saving time and cost. Its innovative center housing, sprocket, shaft, and bearing design—rigorously tested for durability—makes this unique installation possible.

—Joe Hibma, farmer

A proven solution for bin owners and contractors

The Double Barrel Power Sweep reduces installation complexity while providing the performance and reliability bin owners expect from a bin unloading system.

Why contractors like it

The Double Barrel Power Sweep delivers commercial unloading performance with a design that simplifies installation. Engineered to fit a wide range of bin floor heights, it installs in floors as low as 13 inches, eliminating the need for deep concrete tunnels, extensive forming, and costly foundations. The result is reduced labor, lower material costs, and faster installation compared to traditional commercial under-bin systems.

Flexible configuration options allow installers to adapt to real-world job site conditions. The conveyor can be configured to stop at the center of the bin or run full-diameter through the bin, accommodating different unloading layouts without redesigning foundations or bin structures.

Structural demands are reduced through internal support between the twin conveyor tubes, eliminating the need for expensive bridge supports in bins with grain depths up to 60 feet. This simplifies engineering while reducing steel and concrete requirements.

All motors, drives, and controls are located outside the bin, making electrical installation faster and safer. Crews avoid in-bin wiring, explosion-proof components, and collector rings, reducing complexity and long-term service concerns.

The low-profile design makes the Double Barrel Power Sweep ideal for both new construction and retrofit projects, delivering high-capacity unloading performance even where floor height is limited.

Benefits for bin owners

For bin owners, the Double Barrel Power Sweep offers a practical path to commercial-level unloading performance without the cost and complexity typically associated with large under-bin systems. By eliminating tunnels, deep foundations, and excess concrete work, it helps reduce total project cost while still delivering the capacity and durability required for high-volume grain handling.

In tough or stubborn grain conditions where traditional sweep styles struggle, the Double Barrel Power Sweep delivers aggressive, consistent material movement. The MAAT sweep push tractor intelligently responds to changing grain conditions, knowing when to push into the pile, when to stop, and when to reverse. This automated control helps maintain steady grain flow while reducing operator involvement and improving overall unload efficiency.

Faster installation timelines allow bins to be placed into service sooner, helping operations stay on schedule during critical harvest and unload windows. Tall backshields enable effective single-pass cleanout, saving time at the end of the unload cycle and reducing the need for rework. This combination of efficient installation and faster cleanout is especially valuable for both active farm sites and commercial facilities upgrading existing storage.

With unloading capacities up to 6,500 bushels per hour, the system delivers high throughput using lower horsepower and fewer mechanical components than traditional commercial under-bin systems. The result is dependable performance with reduced energy use and minimal ongoing maintenance.

Designed to scale as storage needs grow, the Double Barrel Power Sweep works across bin sizes ranging from 18 to 93 feet in diameter. This flexibility makes it a long-term unloading solution suited for everything from high-capacity farm storage to full commercial grain operations.

The Double Barrel Power Sweep delivers high-capacity bin unloading without the cost or complexity of a traditional commercial under-bin system. Its low-profile design helps reduce installation time and expense, works in both new and retrofit bins, and fits low-clearance floor applications. Built around a proven drag conveyor, it provides reliable performance, smooth grain flow, and a zero-entry operating design that improves safety. The system supports bins from 18 to 93 feet in diameter with capacities up to 6,500 bushels per hour.

Request a quote or more information

Fill out the form below, email sales@sudenga.com, or call 712-475-3301. Our team would be happy to visit with you and answer any questions. With a wide range of applications, the Double Barrel Power Sweep is an ideal solution for both farm and commercial grain storage operations.

SETTING THE STANDARD IN BIN SWEEPS

At Sudenga, we don’t just build power sweeps—we engineer them for the future. With multiple patents and more in the works, our power sweeps are designed with industry-leading technology to deliver unmatched efficiency, durability, and performance.

When you choose Sudenga, you’re getting more than just a sweep—you’re getting patented performance, engineered to last.

___________________________

SUDENGA GRAIN BIN SWEEP PATENTS

U.S. Patent Number 10,017,338

U.S. Patent Number 10,518,989

U.S. Patent Number 10,322,892

U.S. Patent Number 9,650,217

U.S. Patent Number 9,546,055

U.S. Patent Number 9,206,001

U.S. Patent Number 9,206,000

U.S. Patent Number 8,864,433

U.S. Patent Number 8,616,823

Canadian Patent Number 2,691,498

Additional patents applied for

Patents pending