The system automatically adjusts as unloading conditions change

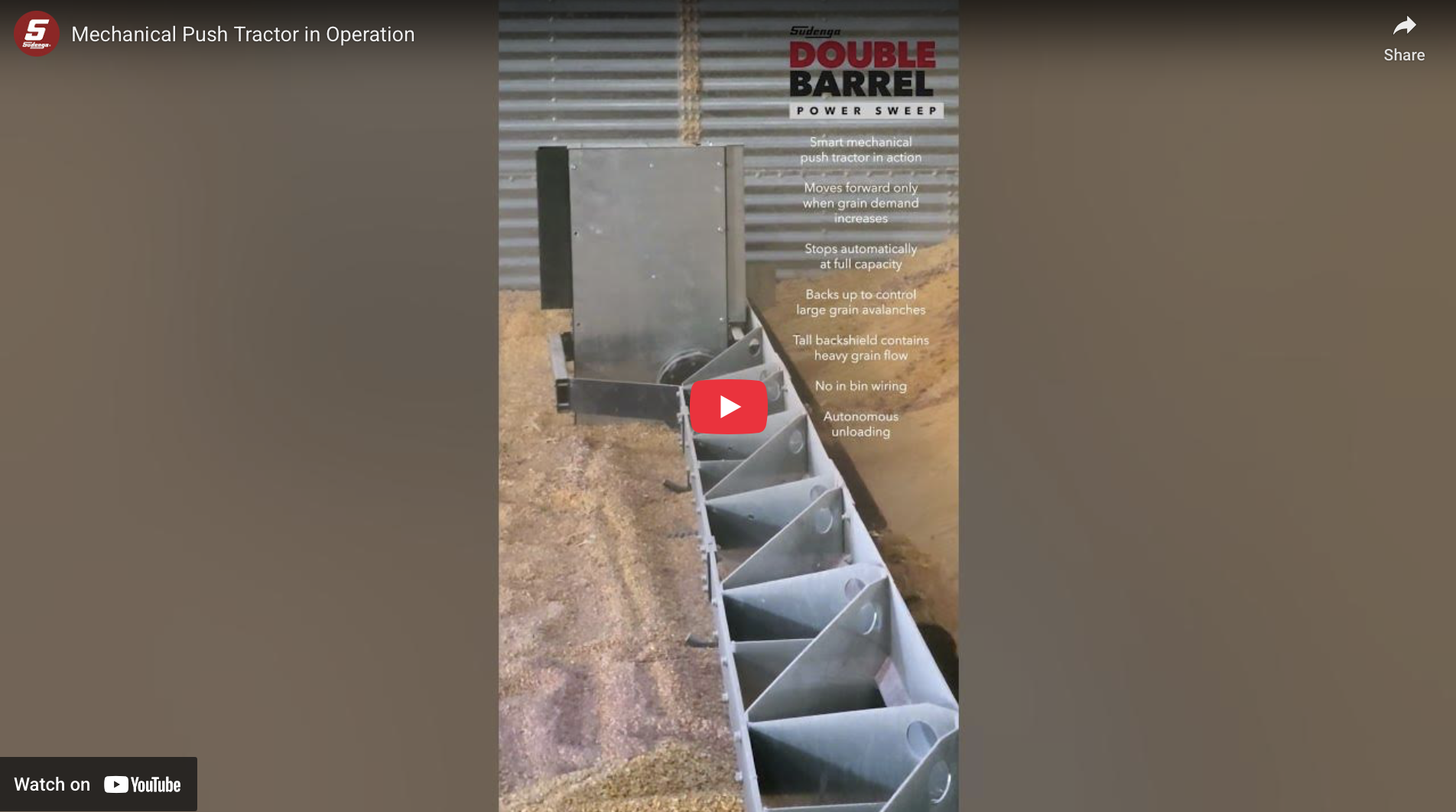

Grain unloading efficiency often comes down to how consistently a sweep can keep grain moving without constant adjustment. The Double Barrel Power Sweep uses a mechanical auto-advance system designed to respond directly to grain load, allowing the sweep to regulate itself as conditions change during unloading.

Rather than relying on electronics or in-bin motors, the system uses a mechanically driven push tractor that advances, pauses, or backs up automatically based on resistance in the sweep auger. This load-based response helps maintain steady grain flow without operator input, supporting a true zero-entry unloading process.

Auto-advance is achieved through a gearbox and PTO arrangement powered by the sweep auger itself. Because the system is fully mechanical, there are no electric motors, controls, or wiring inside the bin. This design reduces complexity and eliminates components that can be exposed to dust, vibration, and harsh operating environments.

As grain enters the sweep auger, resistance increases and is transferred through the mechanical drive system. When load reaches a set threshold, the push tractor slows or stops its forward movement. If load continues to build, the tractor can back up slightly until flow stabilizes. Once resistance decreases, the system automatically resumes forward motion, keeping unloading balanced and controlled.

This direct response to grain load helps reduce plugging and limits unnecessary stress on sweep components and the under-bin conveyor. It also allows the system to adapt as grain depth, pressure, and bin conditions change throughout the reclaim process.

Because the push tractor and sweep arm are self-setting and mechanically driven, the Double Barrel Power Sweep operates without requiring personnel to enter the bin.

LEARN MORE: https://sudenga.com/double-barrel-power-sweep/