- Specifications

- Photos

- Installations

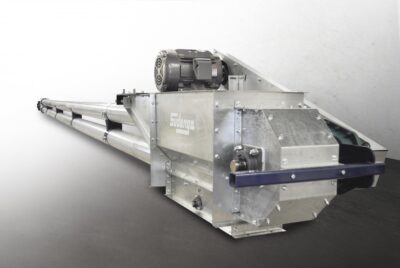

Double Barrel

Why Double Barrel?

- Higher capacity ratings than a like sized round tube auger system.

- Lower horsepower requirements than a like sized round tube or u-trough system.

- Install horizontally, or at inclines up to 60 degrees.

- Better clean out than a traditional drag chain conveyor. Material is moved in a tube with a paddle which matches the tube shape. Grain can’t sit in the corners like it would on a traditional drag conveyor.

- Economical to install. Double Barrels often require less structure to support than a traditional drag conveyor.

- Modular system. All components bolt together, so the system can be tailored to fit the application. Sudenga can supply the outer tubes, or supply your own.

Where to use the Double Barrel?

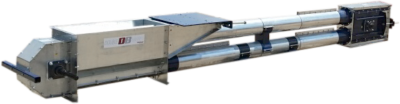

You can use the Double Barrel chain conveyor pretty much anywhere a traditional auger or drag chain conveyor might be installed. Unlike a round tube auger, a chain conveyor doesn’t necessarily require grain in the system to run smoothly and quietly. This benefit makes the Double Barrel a great option for use with a grain dryer. The Double Barrel conveyors are also nice for stationary applications filling a grain bin, or for inclining after a bin unloading system. They can be installed horizontally or at an incline up to 60 degrees and doesn’t necessarily require a catwalk support system like a traditional conveyor might.

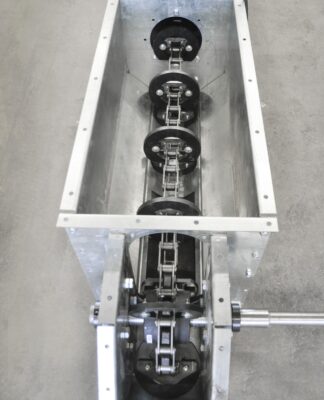

Specifications

- Totally modular.

- All components clamp together.

- Available in 6”, 8”, 10” and 12” diameter systems.

- Galvanized outer tubes standard if supplied by Sudenga.

- Standard and optional heavier gauge tubes available.

- Dodge gear reducers

- Tail mounted drive

- End and intermediate discharges

- Bypass inlet

Optional Features

- Truss kits

- Support stands

- Head mounted drive

- Flow-thru bypass inlet

Capacities

- 6” Double Barrel: Up to 1500 BPH

- 8” Double Barrel: Up to 4000 BPH

- 10” Double Barrel: Up to 6000 BPH

- 12” Double Barrel: Up to 10,000 BPH

Capacities vary with the angle of operation

Angle of operation impacts available length and required horsepower.

Also Known As

Sudenga’s Double Barrel systems are also often called double run conveyors or grain pumps in grain handling industry jargon.

Poultry Barn Installation

Check out this poultry barn featuring Sudenga’s Infinifeed Loop System along with a Double Barrel and Horizontal Chain Conveyor.

Read More

Poultry Barn Site

Check out this turkey barn site that features two Double Barrel Chain Conveyors being used to move poultry feed into the barn.

Read More

Farm Site near Warren, MN

This farm site near Warren, MN features two double-run chain conveyors, a bucket elevator system, and a low-profile receiving pit.

Read More

Farm Site near Adair, IA

Check out this Adair, IA farm site featuring two Double Barrels and low-profile chain conveyor receiving pit from Sudenga.

Read More

Farm Site near Springfield, OH

Check out this Springfield, OH farm site featuring a Double Barrel and low-profile chain conveyor from Sudenga.

Read More