- Specifications

- Photos

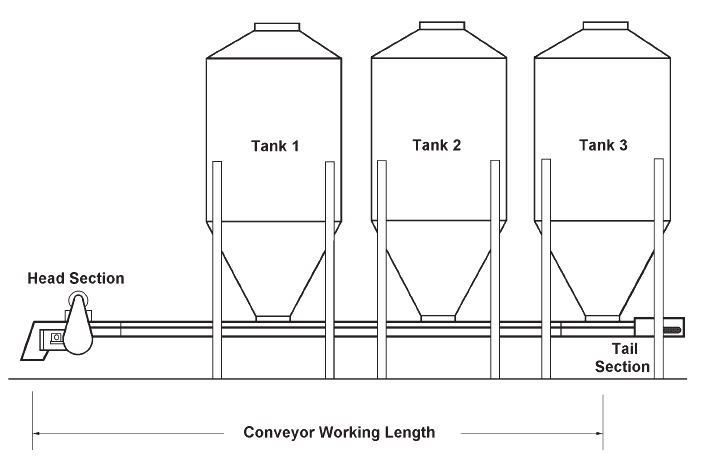

Horizontal Belt Conveyors

STANDARD FEATURES

- 5,000 CFH capacity

- Runs to 100 feet

- 400 FPM belt speed

SPECIFICATIONS

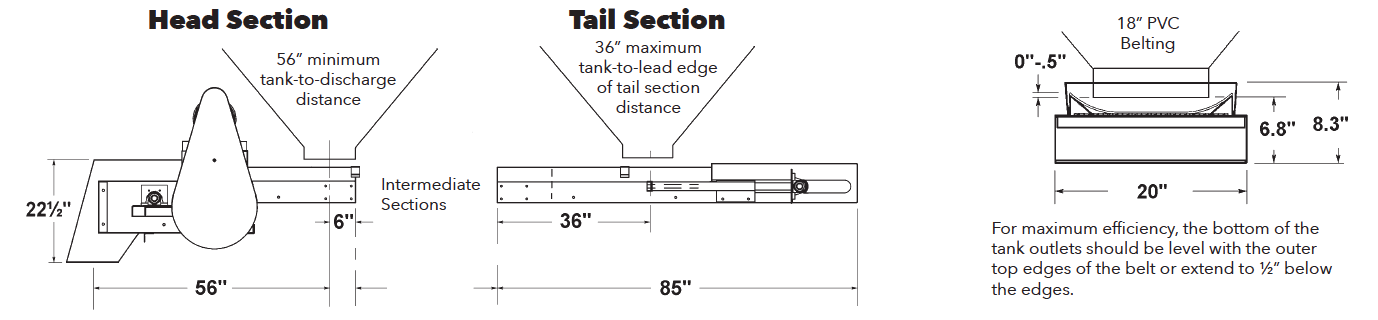

Head Section: Lagged rubber type 8” head pulley. The center of the first tank must be at least 56” from the conveyor outlet to clear the motor (based on a 12” tank outlet).

Tail Section: 4” tail pulley is steel. The last tank can be placed on the tail section up to 36” from the lead edge.

Belting: Friction surface belting rides on an expanded metal slid-er bed and has an “S” wrap drive.

Transitions: 12” square transitions make quick tank-to-conveyor connections.

Return rollers: Return rollers with ball bearings are on 10′ intervals.

ORDERING INFORMATION

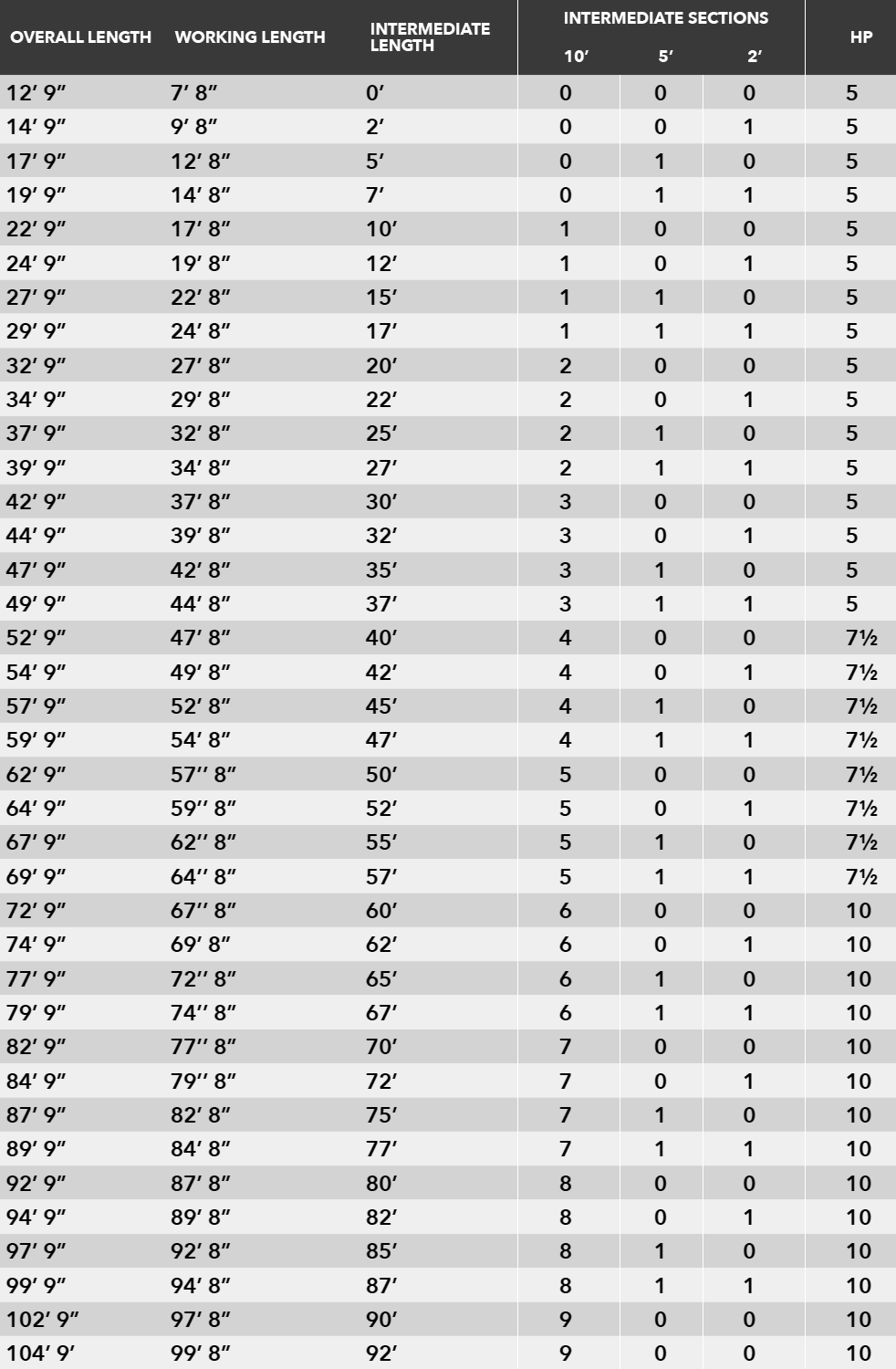

Conveyors consist of a head, tail, and intermediate sections. The conveyor working length (from the center of the last bin to the conveyor outlet) determines the length of intermediate conveyor required. The chart shows the intermediate length and horsepower required, based on working length. Pick a working length just longer than your actual working length. Intermediate sections column indicates quantity of 10′, 5′ and 2′ sections required.