- Specifications

- Photos

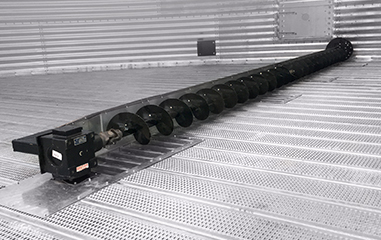

U-Trough Power Sweep

STANDARD FEATURES

Easy installation: Much of the sweep is factory assembled. The 10″ center sump is part of the u-trough. All controls are internal. Just slide the complete assembly through the bin wall and attach the sweep.

Trough hanger bearings: Wood bearings are placed at the sumps for easy access. Flightings and bearings can be removed as a unit, with the bearing hangers sliding on ledges in the trough. Bearings are self-seating.

Sweep stop: Limits the sweep to one revolution. The stop swings back, allowing the sweep to move forward over the sumps before filling the bin.

Heavy duty double gearbox sweep drive: Internally controlled engage/disengagement for the sweep auger. Precision gearboxes are oil-bath types. Featuring 1¼” shafts.

Center sump: Heavy duty rollers or sliders coupled with the standard rack and pinion opener provides smooth gate action.

Sumps: Compare the number of Sudenga intermediate sumps to those on other brands. More sumps means more reliable sweep startup and unloading of the bin. If the center sump becomes blocked during the first phase of unloading the bin, the intermediate sump nearest the center acts as a safety sump and can be opened independently to continue first phase unloading from near the bin center.

►Adjustable top flanges accommodate uneven bin floors.

►Internal sweep engagement controls. Direct coupled heavy duty 1- 1/4″ shaft gearboxes.

►Reinforced galvanized sweep back-shield for one-pass sweep operation

►All control rods located inside the u-trough. Factory installed.

►Rack & pinion gate opener makes for smooth, positive control for opening and closing gates.

►Horizontal and incline unloading heads available.

Works with 13" floor

DID YOU KNOW?

Sudenga’s 12″ u-trough power sweep is the only bin or silo sweep of its kind – it’s designed to install in a 13″ grain bin or silo drying floor while handling up to 10,000 bushels per hour.

CAPACITIES

| Unloading Auger | 10″ System | 12″ System |

|---|---|---|

| Horizontal | 6,000 BPH | 10,000 BPH |

| 27 Degree Incline | 5,200 BPH | 10,000 BPH |

Capacities are approximate and for underbin auger only. Capacities are reduced when the sweep auger is engaged.

SPECIFICATIONS

| Trough Ga. | Flight Dia. | Flight Ga. | Flight Pipe | Flight Shaft | |

|---|---|---|---|---|---|

| 10″ Underbin | 14 | – | 1/4″ | 2 7/8″ | 1 1/2″ |

| 10″ Sweep | – | 7 1/4″ | 1/4″ | 2 7/8″ | 1 1/2″ |

| 12″ Underbin | 10 | 1 | 1/4″ | 2 7/8″ | 1 1/2″ |

| 12″ Sweep | – | 11 1/4″ | 1/4″ | 2 7/8″ | 1 1/2″ |

End Wheel

SWEEP END WHEELS

| For 10″ Systems | For 12″ Systems | |

|---|---|---|

| 11:1 Molded End Wheel | Standard (Bins 15′ to 43’4″) |

– |

| 20:1 Molded End Wheel | Standard (Bins 48’+) |

Standard (All bin sizes) |

BENEFITS OF MOLDED END WHEEL

►Universal 16” diameter molded tire for all bin sizes

►Increased amount of available tread to improve wear life

►Improved density for optimum balance between traction and life

►Deeper reductions for improved wheel life and traction

OPTIONS

CLEAN SWEEP BRISTLE

►Sudenga’s clean sweep bristles drastically reduce the amount of grain left behind. Work smart, not hard.

►Optional on 10″; standard on 12″.

AUGER EXTENSIONS

►Installed between underbin trough and unloading auger, allowing you to move the discharge point away from the bin.

►Available in 2, 4, 5, 6, 8 and 10 feet lengths

Unloading Augers

Sudenga’s 10″ and 12″ u-trough power sweeps are available with two types of unloading augers:

►Horizontal head

►Inclined head, 27°